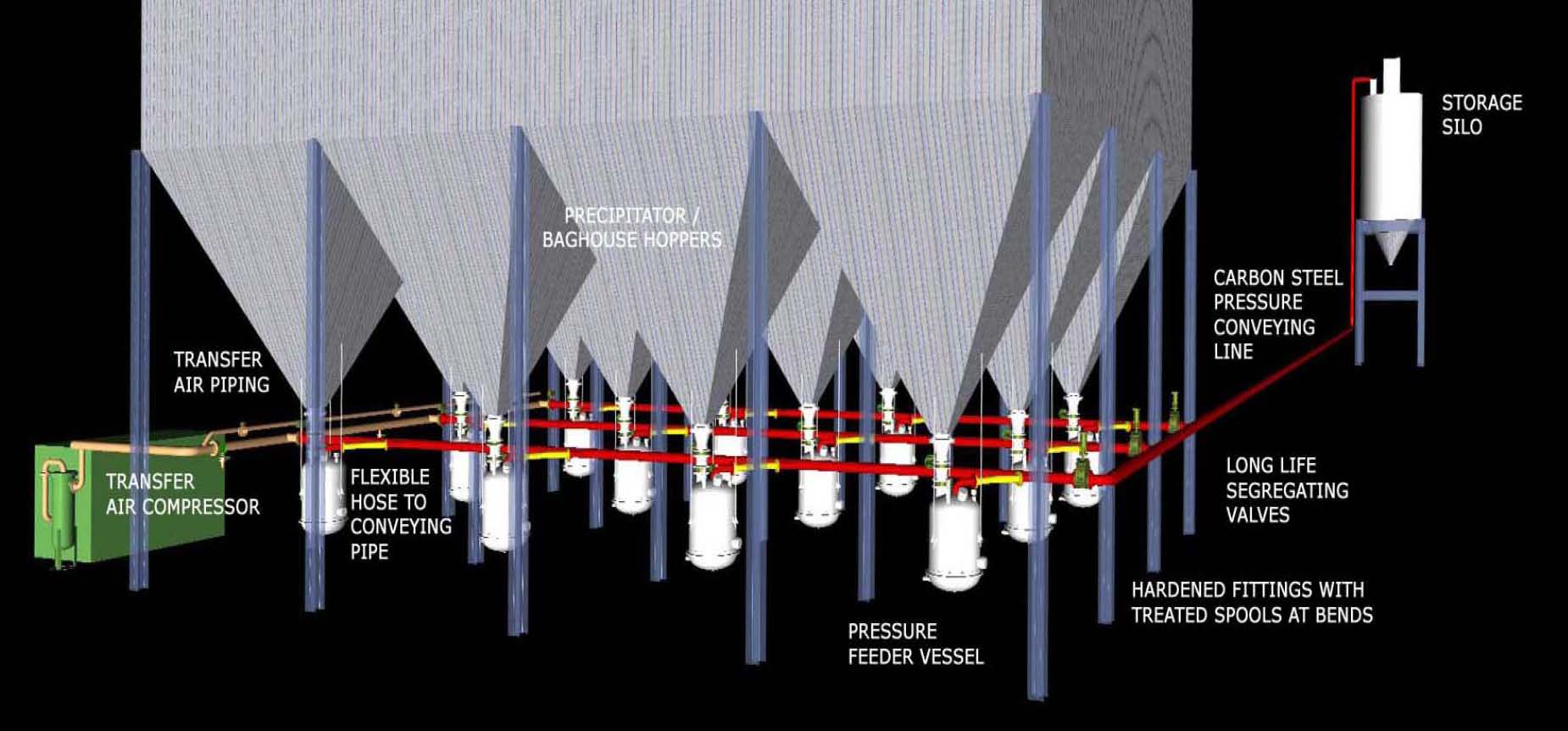

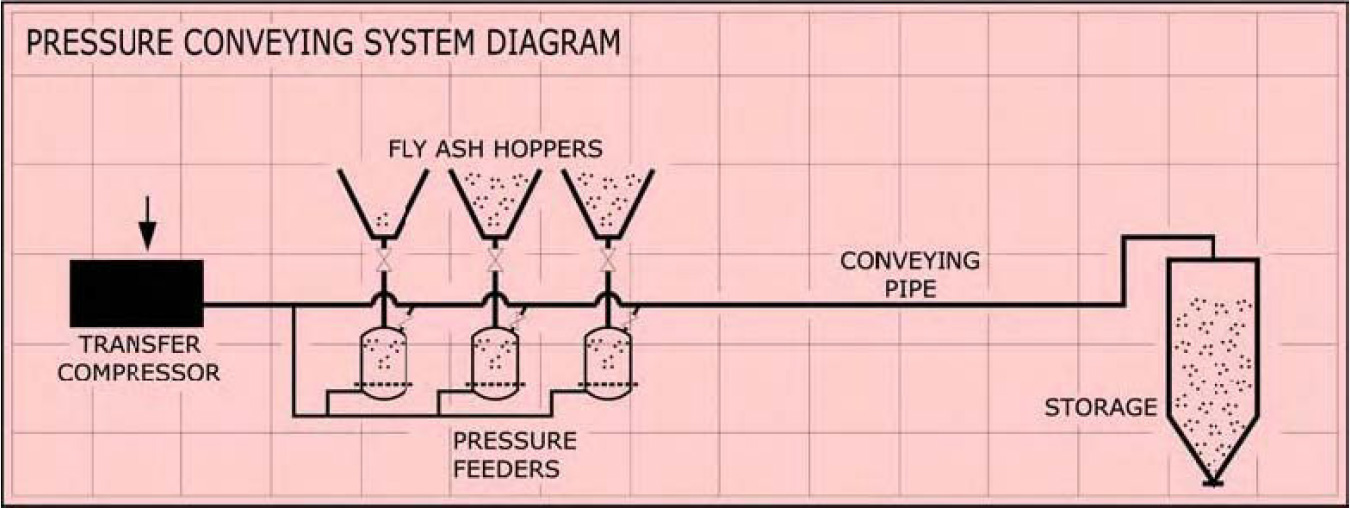

Pressure fly ash conveying is the system often specified for new installations to transfer moderate to large amounts of material to storage / loadout facilities at remote locations of the plant.

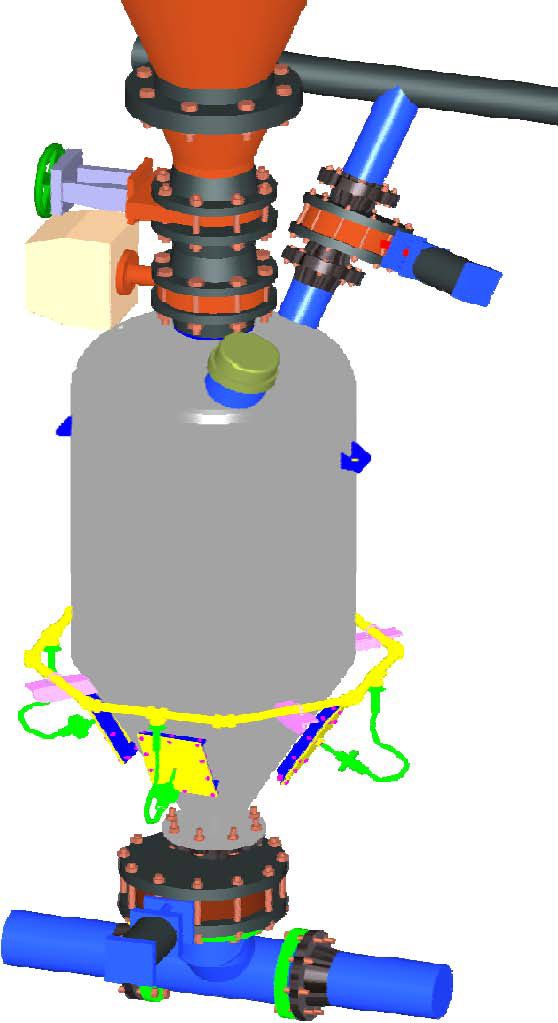

View the system diagram below to see the components comprising the pressure conveying system. A rotary screw compressor produces transfer air to supply pressure feeder vessels and the conveying line. Automatic hopper valves open in sequence allowing fly ash to fall into a pressure feeder vessel under each hopper.