Pneumatic Conveying Design

Pneumatic conveying involves the movement of free-flowing granular bulk solids through an enclosed pipeline by vacuum or with compressed air. Other compressible gasses such as Nitrogen may sometimes be used.

The ratio of the mass flow of solids to conveying air is an indication of whether pneumatic conveying is occurring in a “Dilute Phase” or “Dense Phase” regime. In dilute phase conveying, the solid particles are suspended in the conveying air whose velocity must be above the minimum “pick up velocity” for the material. Dense phase conveying can occur as plug flow or as a moving fluidized bed. The higher velocities in dilute phase conveying usually mean higher power consumption and more pipe wear. Plug flow is practically limited in capacity and distance. Moving fluidized bed dense phase flow can achieve high capacities at long distances with lower power consumption.

Material characteristics will determine the most suitable pneumatic conveying regime for your material. Some granular materials cannot retain air and must be conveyed in dilute phase. Fluidizable powders which retain air such as fly ash or cement are ideal candidates for moving fluidized bed dense phase conveying.

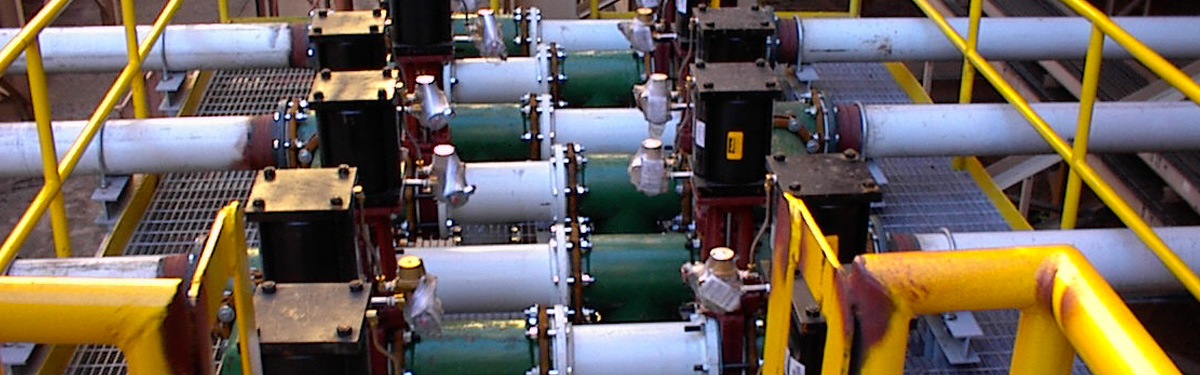

Pneumatic conveying systems have several advantages over mechanical systems. A pneumatic conveyor is a fully enclosed pipeline which eliminates material contamination, material loss and dusting. This enhances environmental protection and safety. Pneumatic conveyors are quieter than mechanical systems. Clean out, cleanup and maintenance are simpler since all the moving parts are external to the conveying pipeline. Pneumatic conveyors are much more flexible in routing. Material can be conveyed long distances with multiple changes in direction and elevation. Modifications of conveyor routing or the addition of new destinations are easy to make.

LBIS has pioneered the development and expanded the limitations for pneumatic conveying of fly ash. We have developed vacuum reclaim from large, flat floor storage tanks and domes combined with pressure distribution to multiple loadout silos. We have provided dense phase pressure pneumatic conveying systems capable of transporting fly ash over two miles at 250 tons/hour. These technologies can also be applied to other materials.

LBIS maintains an extensive database of the properties of materials which have been pneumatically conveyed in our systems. For these materials we apply proprietary equations to derive pipe size(s), air requirements and power requirements for a particular material conveying capacity, distance and pipe routing. The accuracy of these calculations has been verified through field data logging during performance testing of completed systems. Standard lab tests can be performed on your material to determine its properties and the results compared to the database of materials whose properties and conveying / handling behaviors are known. For materials outside the scope of our database, pneumatic conveying tests can be performed in our laboratory piping loop and the results scaled up to predict the performance of your material in a full-sized system of the desired configuration in your plant.