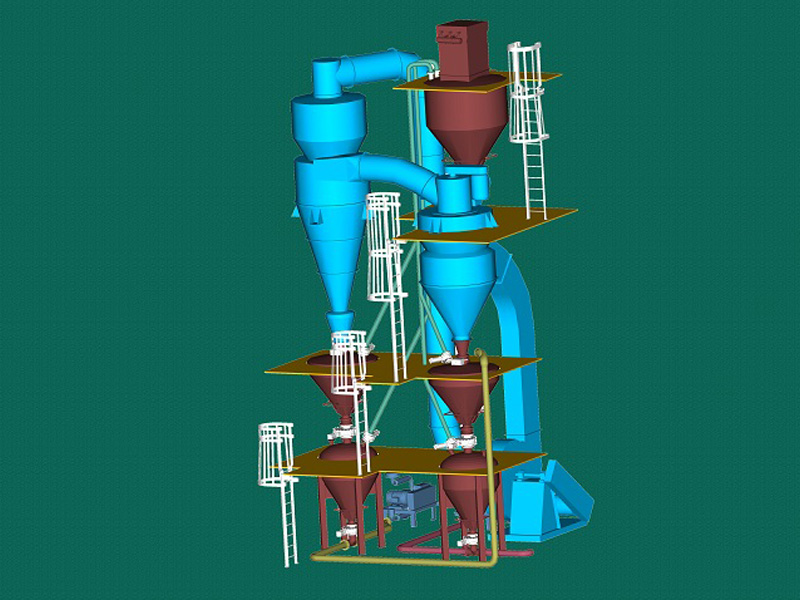

Air classification is a common method for separating a powdered or granular material into a fine and a coarse fraction. It balances a centrifugal force against an aerodynamic force to effect the separation of particles. Coarse particles report to one discharge port while fine particles report to a different discharge port.

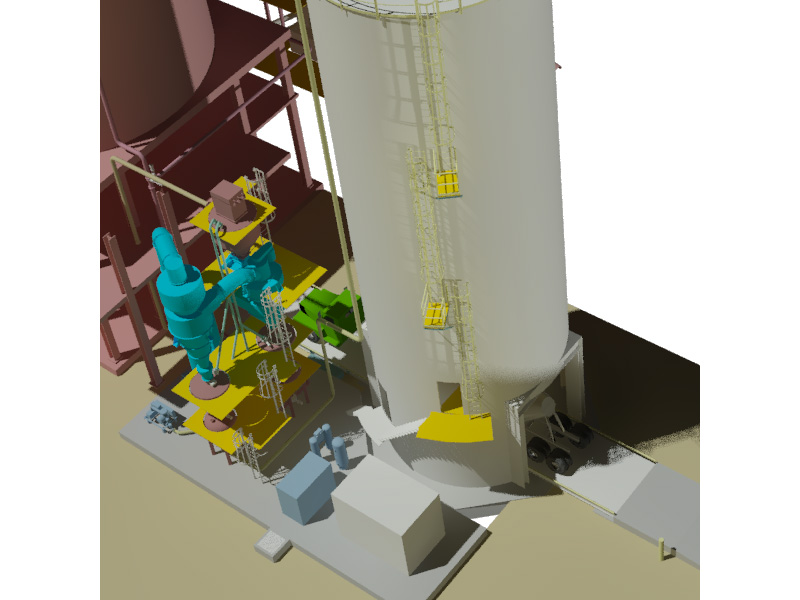

The centrifugal force is usually provided by a rotating wheel while the aerodynamic force is induced by a fan driving air through the classifier circuit. Separation is affected by particle density as well as particle size. This differs from a screening process that separates strictly by particle size based on the size of the holes in the screen. The design of a classification system usually involves some trade-offs. For example, a more precise separation will usually be accompanied by a lower processing rate. Classifiers generally have a higher processing capacity than screens and classifiers are better suited for the separation of ultra-fine materials. Classifiers provide separation at one cut point while screens can provide multiple separations. A classifier system will require three silos with attendant conveying/feeder systems; feed material, coarse fraction, and fine fraction.