Long distance conveying, dense phase conveyor, fly ash handling system, pneumatic conveying system

Bulk-Powder-Conveying

Valved bypass for a pneumatic conveying run.

Pneumatic conveying transport vessel design, bulk powder conveyor, transfer vessel, pneumatic conveying pressure pot.

Dilute-Phase-Pneumatic-Conveying

Bulk powder conveying transfer vessel designed for dilute phase pneumatic conveying feeder system.

Pneumatic conveying transport vessel design, bulk powder conveyor, transfer vessel, pneumatic conveying feeder vessel, pneumatic conveying pressure pot.

Pneumatic-Conveying Feeder-Vessel

Bulk powder conveying transfer feeder vessel design image.

High volume transfer vessels, long distance pneumatic conveying system, dense phase conveying, pressure transport vessel

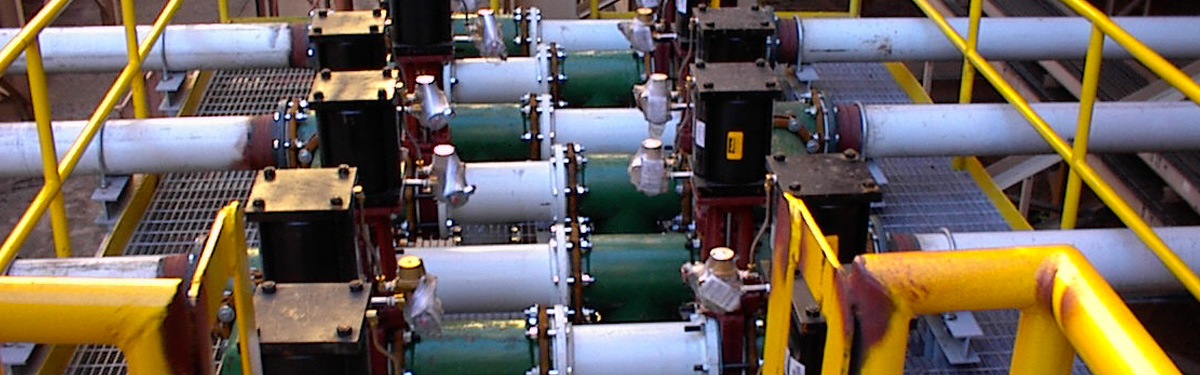

Pneumatic Transfer System

Installation of two pressure transport vessels for long distance pneumatic conveying system.

Pneumatic vacuum collector, pneumatic transfer vessel, pneumatic transfer system installation, pneumatic conveying filter separator.

Pneumatic-Transfer-Vessel-Installation

Installation pneumatic transfer vessel and vacuum filter separator for a combination of vacuum and pressure transfer station.

Lower wearing pipeline, computerized conveying calculations, pneumatic conveying experts

Material Profile within pipeline, Pipe size changes to control velocities and thus wear

Material Profile within pipeline, Pipe size changes to control velocities and thus wear

Dilute phase conveyor, fly ash handling system, pneumatic conveying system, powder conveying system

Dilute-Phase-Pneumatic Conveying

Model image of a dilute phase vessel for a pneumatic conveying system.

Pneumatic conveying, transport vessels, dense phase, transfer vessel, long distance conveying, dense phase conveyor system.

Pneumatic Dense Phase Conveying

Design image for dense phase transfer vessel.

Pneumatic Conveying Pressure Vessel

Two dense phase transfer vessels installed below vacuum collector filter separators, for a long distance pneumatic conveyor system.

Long distance conveying, dense phase conveyor, fly ash handling system, pneumatic conveying

Pneumatic Conveying Long Distances

Long distance fly ash conveying system, with elevated pipe supports for truck clearance across roadway.

High Pressure Transfer Vessel

High Pressure Transfer Vessel

700 PSI Rated Transfer Vessel

Long distance conveying, dense phase conveyor, fly ash handling system, pneumatic conveying

Pneumatic Conveying Long Distances

Long distance fly ash conveying system, with elevated pipe supports for truck clearance across roadway.