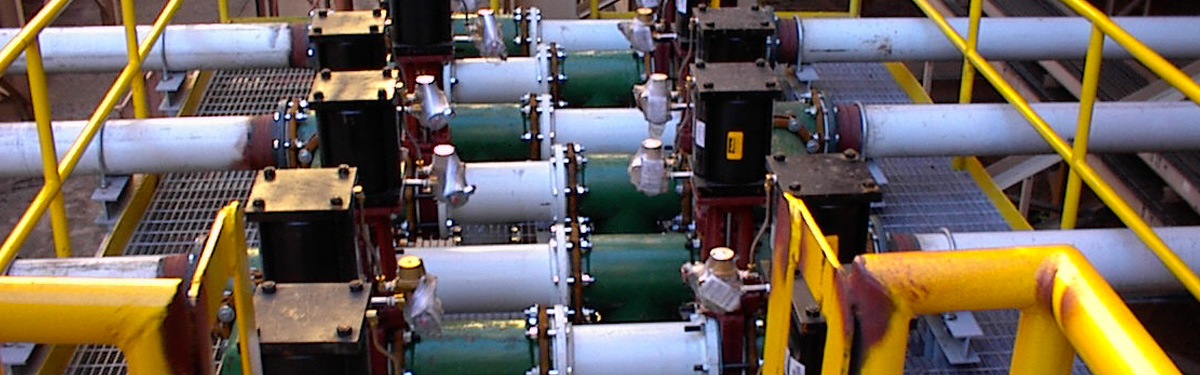

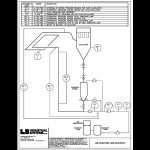

LBIS maintains a pneumatic conveying laboratory where we perform various bench-scale tests, and operate a pneumatic conveying test loop. The test loop includes a filter/receiver, pressure vessel, two-inch bore piping, and a high-pressure air supply. It is fully instrumented and equipped with data logging equipment. We perform conveying tests at various air and material flow rates, then scale up the data to predict performance in full-sized plant systems. We have field verified the performance of the completed full-sized systems on a number of occasions.

LBIS also works with equipment manufacturers to size and predict the performance of their equipment. For example; classification tests verify expected to yield at various feed rates and cut points.

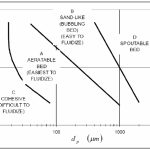

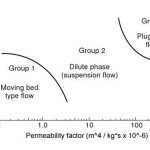

Knowledge of certain physical properties of a material is important to understand it’s expected conveying, processing, and storage behavior in your plant. Standard tests are performed on the material to determine its properties and the results are compared to a database of known materials whose properties and conveying / handling behaviors are known. The comparison yields expectations about the conveying and handling characteristics of the subject material. This is called “Material Characterization”.

Some tests provide data for direct calculation of equipment sizing. Other tests provide data for comparison with similar materials whose performance is known.

Typical tests include: